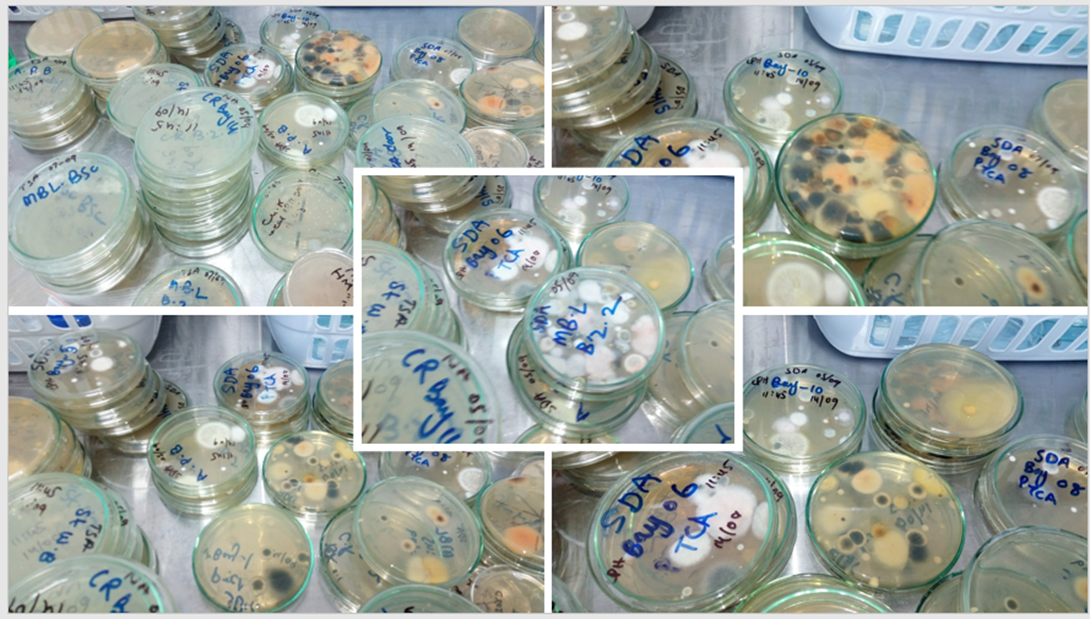

MICROBIAL LOAD TEST: Bioburden Test

Bioburden OR Microbial load testing (MLT) is a regulatory requirement and is critical for process development of biological, pharmaceutical, surgical, and dental and other medical devices i.e., catheters and stents along with systems. It is an important test for raw material, semi-finished and finished product. It can provide an accurate basis for calculating effective sterilization doses and will provide the quantity of viable microorganisms in or on product or raw material before sterilization. Bioburden testing is applicable for: Lot Release Testing Final Product Testing Raw Material Testing Semi-finished Product Testing Contact us about your bioburden testing needs. Microbiology.com can provide all these services in accordance with ISO 11737, USP <61>, USP <62>.